LED Times

Litecool has produced LED packages in a vertical orientation rather than horizontal. a minor impact on the thermal performance of the LED package and allow the heat to escape more effectively through the metallic parts of the package. This has significant benefits for flip-chip packaging where dielectric layers are usually very close to the diode.

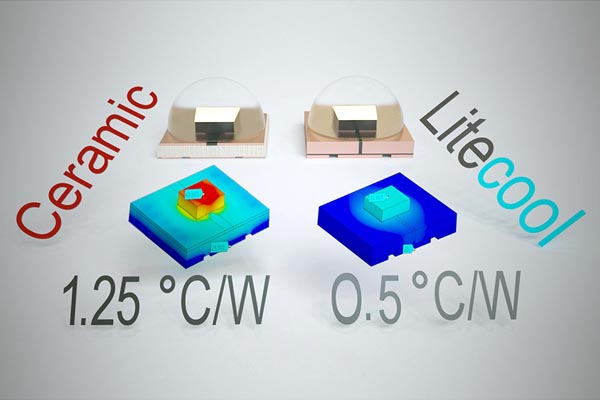

Dielectrics are used within LED packages to isolate electrical tracks but they hinder the thermal path causing the LED to overheat. In the construction of conventional LED packages the electrical tracks and dielectrics are layered horizontally. This means the heat has to pass through one or more low-conductivity dielectric layers causing thermal bottlenecks. By turning this layering by 90 degree the heat can travel down through the copper tracks and not through the dielectric. The thermal resistance [°C/W] of packages produced in this way is 3 times lower than conventional packaging. This lower thermal resistance means that heat sinking requirements are vastly reduced and the LEDs can be driven much harder for more light output.

The Vertical Dielectric technology (Patent Pending) allows for close packaging of multiple LEDs within one package with minimal effect on thermal performance as well as significant reductions in the thermal resistance of flip-chip packages. The 'track and gap' constraints of traditional electronics manufacture are removed allowing for more flexibility in thermal design.

One of the key commercial benefits is that the dielectrics no longer need to be expensive ceramics with high thermal conductivity. Cheaper polymer based dielectrics can be used as their thermal impact is negated. Litecool has developed designs and manufacturing processes to allow such packages to be manufactured in high volume.

"It is not a difficult concept to design but it is difficult to manufacture. We have had to develop new manufacturing processes to allow for the unprecedented track and gap ratios required and it has resulted in performance way beyond anything else on the market." Robert Corbin, Project Engineer, Litecool.