Margery Conner

EE Times

LED bulb prices are dropping. A year ago you could expect to pay $50 for a Philips dimmable 60W-replacement LED bulb, while today you can go to Best Buy and purchase its house brand 8W, 800 lumens Insignia 60W-replacement bulb for just $17. What has changed in LED bulb design to allow this price drop? Tearing apart the bulb gives us a look into some design trends in LED lighting, such as how the LEDs are placed within the bulb and what driver architecture is used.

The Insignia bulb has a shape similar to the familiar incandescent light, with the addition of three metal heat sink fins, and a plastic bulb instead of glass (Figure 1).

|

|

| Figure 1. | |

Dimming is an important bulb characteristic for the US market. I used a Lutron Maestro dimming switch, with a programmable dimming control, and did a side-by-side comparison with an incandescent bulb. The Insignia dimmed consistently and smoothly, with a dimming profile similar to the incandescent bulb. You can watch a video of the dimming test here.

The next step was to look inside the bulb and see how the LEDs are mounted. Figure 2 shows the plastic bulb cover removed with a Dremmel tool, exposing the six Cree white LEDs that illuminate the bulb's light mixing chamber that allow an even glow with no pixelation. The metal fins that the LEDs are mounted on serve to both elevate the LEDs and serve as heat sinks.

|

|

| Figure 2. | |

At the bottom of the mixing chamber is a paper-thin aluminum reflector that helps reflect the light up and out of the bulb.

All of the electronics for this bulb lie beneath the mirror in the base of the bulb, in a separate and encapsulated compartment (More detailed photos are here).

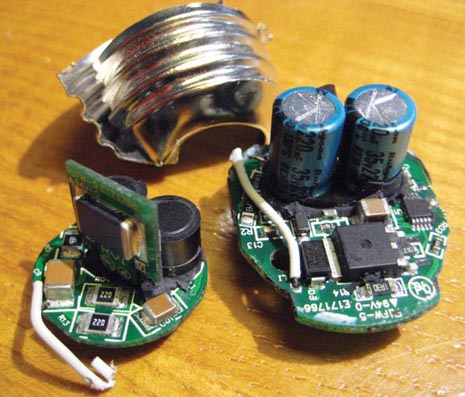

Removing the rubbery potting compound shows that the electronics are mounted on two separate pc boards that nestle together. Figure 3 shows the two pc boards separated and next to the bulb's base.

|

|

| Figure 3. | |

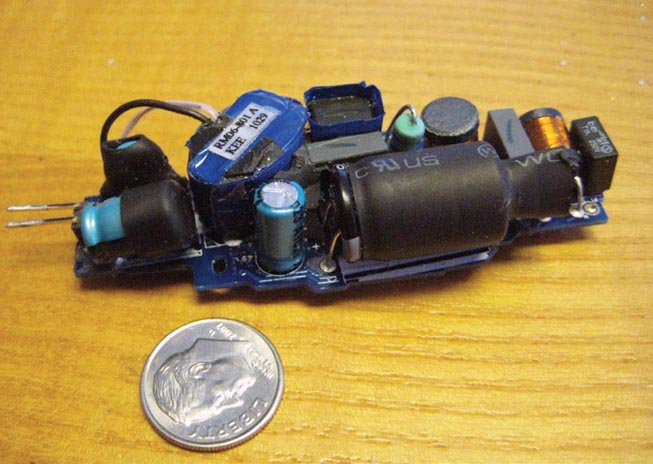

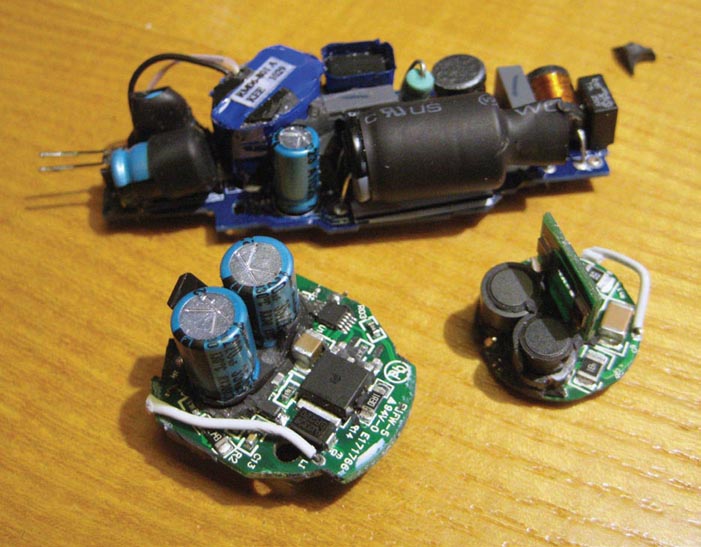

For comparison purposes, Figure 4 shows the driver electronics for a LED light teardown from about a year ago. Not only is the packaging quite different, but there are a lot more electronics. For example, there are three electrolytic capacitors in the older design and a very large transformer.

|

|

| Figure 4. | |

Figure 5 shows the two different generations of drivers side-by-side: The Insignia driver has just two relatively small e-caps. This begs the question: What LED driver IC does the bulb use, and how does it allow such a tiny driver?

|

|

| Figure 5. | |

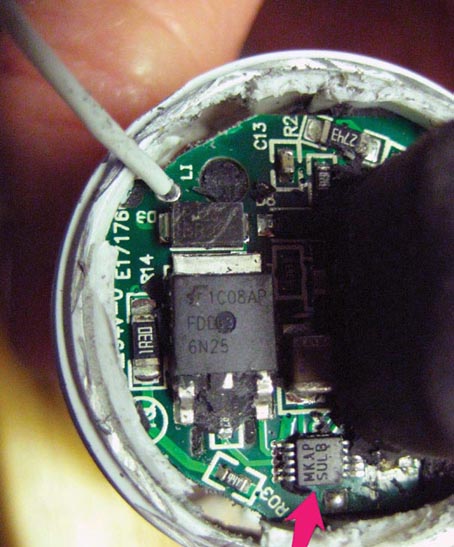

Figure 6 answers this question: The “SUL B” on the tiny IC is the marking for the Texas Instruments LM3445. There is no transformer, indicating that the LED driver design is non-isolated.

|

|

| Figure 6. | |

There is certainly precedent for non-isolated light bulbs: The incandescent bulb design itself is non-isolated. If you broke the glass in an incandescent bulb while it was plugged in, you would have direct access to the AC line power. Clearly, non-isolated designs can be made fully compliant with UL specifications. (While a non-isolated AC-DC LED driver design can be both safe and meet UL specifications, keep in mind that developing and testing a non-isolated offline LED driver in the lab requires stringent lab safety procedures.)

To get an idea for the actual LED driver circuit design, we can turn to the TI application note AN 2061 LM3445 A19 Edison Retrofit Evaluation Board (PDF) for a non-isolated buck converter. The schematic is shown in Figure 7.

|

|

| Figure 7. | |

In order to have the LED drive electronics all fit into the base, the Insignia's designers broke the single rectangular board up into the two circular-shaped pc boards (shown back in Figure 3) which fit into the base of the bulb, separate and mechanically isolated from the LEDs. The only wires that come into the bulb are the low-power DC wires that vary between approximately 8-9V. More details and photos on the dimming control performance are here.

In summary

- Placing the Cree LEDs on the three heat sinks that were part of the surface of the bulb. This quickly gets rid of the heat and keeps it separate from the power electronics.

- Forcing the bulb to meet the same, familiar envelope of the incandescent light, which in turn forced the power control electronics to fit into the tiny base.

- Going with a non-isolated buck topology to lower the parts count. Fewer parts = lower cost, smaller size, and greater reliability.

The Insignia bulb is currently one of the best values for an LED bulb on the market.