They both have advantages and limitations. So which one is right for your application?

It is an engineering truism that there is no such thing as a perfect solution – just the best solution for the problem at hand. That holds particularly true for servo motors and stepper motors. Both are broadly used in industry. Neither is a universal solution. When properly applied, however, both stepper and servo motors can provide effective, reliable power for a highly successful system. The decision tree for choosing between the two has many branches, but the most important are speed, acceleration and price target.

Stepper motors

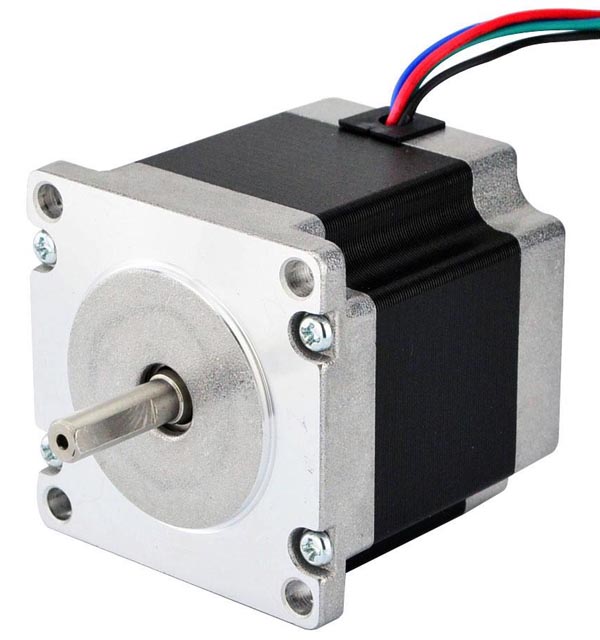

Stepper motors (Figure 1) consist of a rotor with permanent magnets and a stationary stator that carries the windings. A current running through the stator windings generates a magnetic field that interacts with the rotor’s magnetic field to create and apply a turning force. Stepper motors feature high pole counts, typically 50 or more. Each pole is energized in sequence by the motor’s driver so that the rotor turns in a series of increments, or steps. But because of the high pole counts, the motion appears continuous.

|

|

| Figure 1. | Stepper motors deliver good performance at an economical price point for applications requiring low speed, acceleration and accuracy. |

Stepper motors have several attributes. They generate incremental motion and generally run open-loop, and this eliminates the cost and complexity of an encoder or resolver. The high pole count lets them generate high torques at zero speed. They are also compact and generally economical.

On the downside, stepper motors’ speeds are limited. They generally run well at 1,200 rpm or lower. And although they generate high torques at zero speed, torque falls off as speed increases. A motor that generates 100 oz-in at zero speed might only deliver 50 oz-in at 500 rpm and just 10 oz-in at 1,000 rpm (Figure 2).

In theory, adding a gearbox could increase torque, but then the stepper’s low speed would be a problem. Adding a 10:1 gear reducer to a 1,200-rpm stepper motor might boost the torque by an order of magnitude but it will also drop the speed to 120 rpm. If the motor is driving a ball-screw actuator or something similar, it probably will not deliver enough speed to satisfy the application’s needs.

Stepper motors generally are not available in frame sizes larger than NEMA 34, with most applications falling in NEMA 17 or NEMA 23 motor sizes. As a result, it is unusual to find stepper motors that can produce more than 1,000 to 2,000 oz-in of torque.

Stepper motors also have performance limitations. For example, the motor needs to break friction to begin turning and move the load, at which point the rotor is not fully controlled. As a result, a command to advance by five steps may result in the motor turning four steps – or maybe six.

If the drive commands a motor to advance 200 steps, however, it will do so to within just a few steps, which at that point represents an error of a few percent. Although stepper motors have resolutions typically between 25,000 and 50,000 counts per revolution, the motor is a spring-mass system under load and the typical resolution is 2,000 to 6,000 counts per revolution. Still, at these resolutions, even a 200-step move corresponds to a fraction of a degree.

Adding an encoder will accurately track movement, but it will not overcome the basic physics of the motor. For applications that need better positioning accuracy and resolution, servo motors (Figure 3) are a better choice than stepper motors.

|

|

| Figure 3. | Servo motors use closed-loop feedback to deliver better accuracy, speed and acceleration than stepper motors. |

Servo motors

A stepper motor consists of a rotor with permanent magnets and a stationary stator with the windings. Just as in stepper motors, the current creates a magnetic field that acts on the rotor to develop torque. But servo motors have significantly fewer poles than stepper motors. As a result, they must run under closed-loop control.

In general, serve motors run significantly faster than steppers, with speeds on the order of several thousand rpm. This lets servo motors be used with gearboxes to deliver much higher torque at useful speeds. They also deliver more consistent torque across the motor’s speed range of the motor.

Unlike stepper motors, they do not have holding torques. Closed-loop operation lets the controller/drive command that the load remain at a specific position, however, and the motor makes continual adjustments to hold it there. Thus, servo motors can deliver de facto holding torque.

Servo motors typically use rare-earth magnets while stepper motors more frequently use less-expensive conventional magnets. Rare-earth magnets help servos develop more torque in smaller packages. Servo motors also gain a torque advantage from their larger size. Servo motor diameters typically range from NEMA 17 all the way up to 220 mm. As a result of these combined factors, servo motors deliver torques of up to 250 ft-lb.

Servo motors have the speed and torque to deliver higher accelerations than stepper motors. They also deliver more accurate positioning, thanks to closed-loop control.

Final comparisons

Servo motors offer an undeniable performance advantage. In terms of repeatability, however, stepper motors are competitive.

When it comes to costs, stepper motors typically don’t need feedback, use less expensive magnets and rarely have gearboxes. They also have high pole counts, the ability to generate holding torque and they consume less power at zero speed. As a result, stepper motors can be up to an order of magnitude less expensive than comparable servo motors.

So when an application is forgiving but the budget isn’t, consider stepper motors. If performance is paramount, servo motors will do the job – but be prepared to pay more.