CNC Routers and CNC Milling Machines: Precision Tools Shaping Modern Manufacturing

Revolutionizing Precision: CNC Technology’s Role in Modern Manufacturing

The manufacturing sector is experiencing a dynamic shift, propelled by CNC (Computer Numerical Control) technology, which has redefined the production of intricate components and innovative designs with exceptional precision. Central to this transformation are two indispensable tools: CNC routers and CNC milling machines. Though both leverage automated, computer-guided systems, their functions, strengths, and material specialties vary dramatically. This article delves into their distinct roles, industry influence, and spotlights Wattsan—a trailblazing brand at the forefront of CNC advancements.

CNC Routers: Precision Meets Flexibility for Softer Substrates

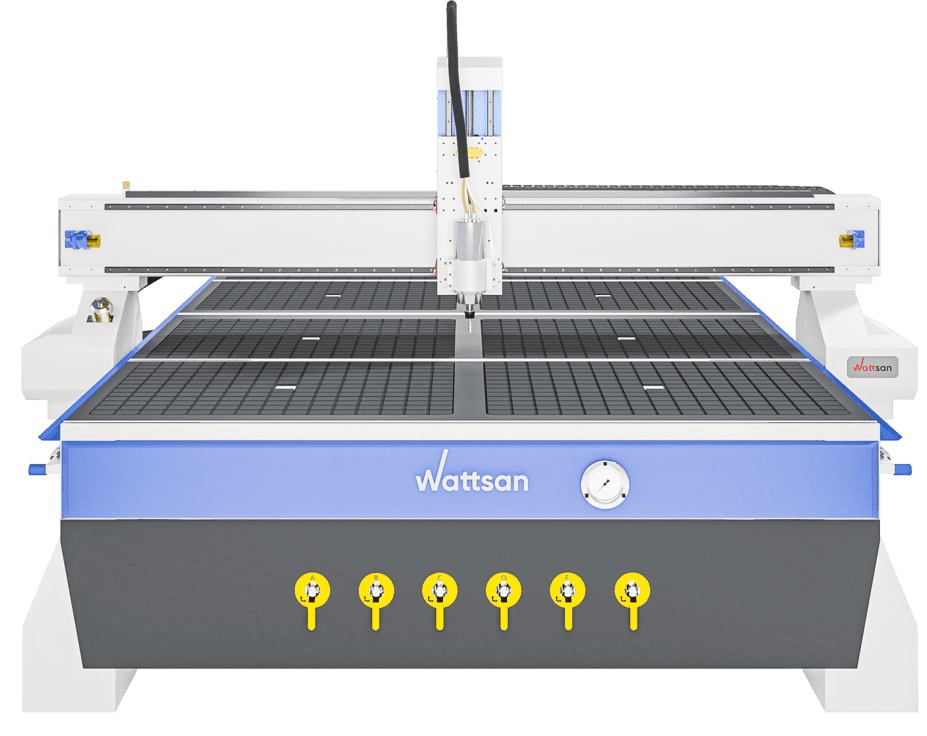

CNC routers are celebrated for their versatility in sculpting, cutting, and forming less dense materials, including wood, plastics, foam, and lightweight metals such as aluminum. These machines are outfitted with high-speed spindles (ranging from 8,000 to 24,000 RPM), enabling them to swiftly remove material—a feature perfect for intricate engraving projects, custom signage, furniture fabrication, and rapid prototyping. Their gantry-based architecture facilitates expansive workspaces, effortlessly handling large sheet materials for seamless production.

Wattsan’s Contribution: Wattsan’s CNC router series, such as the Wattsan A Series, combines affordability with performance. These routers feature user-friendly interfaces, robust frames for stability, and compatibility with popular CAD/CAM software. Designed for small workshops and large factories alike, Wattsan routers emphasize precision in woodworking and creative industries, offering options for 3-axis and 4-axis configurations to handle intricate 3D designs.

CNC Milling Machines: Powering Heavy-Duty Industrial Applications

CNC milling machines are engineered for tougher tasks, capable of machining hard metals like steel, titanium, and alloys. With slower spindle speeds (1,000–6,000 RPM) but higher torque, they remove material methodically, ensuring precision in aerospace components, automotive parts, and medical devices. Their rigid structures and advanced cooling systems prevent deformation under high-stress operations.

Wattsan’s Expertise: Wattsan’s milling machines, such as the Wattsan M-Pro Series, showcase durability and adaptability. Built with cast iron frames and multi-axis capabilities (up to 5-axis), these machines cater to industries demanding micron-level accuracy. Features like automatic tool changers and IoT-enabled monitoring reflect Wattsan’s commitment to integrating cutting-edge technology for enhanced productivity.

Key Differences at a Glance

-

Materials: Routers handle soft materials; mills tackle hard metals.

-

Speed vs. Torque: Routers prioritize speed; mills focus on power.

-

Design: Routers use gantry systems; mills employ sturdy column structures.

-

Applications: Routers dominate woodworking and signage; mills thrive in aerospace and tooling.

Industry Applications

-

Furniture & Decor: CNC routers craft custom designs in wood and acrylic.

-

Aerospace: CNC mills produce turbine blades and structural components.

-

Automotive: Both tools create prototypes, molds, and precision parts.

-

Art & Education: Routers enable artistic creations and STEM learning.

Wattsan: Bridging Innovation and Accessibility

As a global CNC manufacturer, Wattsan stands out for blending advanced technology with user-centric design. Their machines cater to diverse needs:

-

Affordability: Offering competitive pricing without compromising quality.

-

Customization: Tailoring solutions for specific industry requirements.

-

Support: Comprehensive training and after-sales services ensure seamless adoption.

Wattsan’s R&D focus on energy efficiency and smart automation positions them at the forefront of Industry 4.0, empowering businesses to scale production sustainably.

The Future of CNC Machining

With trends like AI integration and hybrid manufacturing rising, CNC tools will become even more intuitive. Wattsan continues to lead this charge, developing machines that reduce waste, enhance precision, and democratize access to high-end manufacturing.

Whether you’re a craftsperson or an industrial engineer, understanding the strengths of CNC routers and milling machines—and choosing a reliable partner like Wattsan—can unlock new possibilities in creativity and efficiency.