Integration of Eva 2.0 Welding Complex into a Production Line

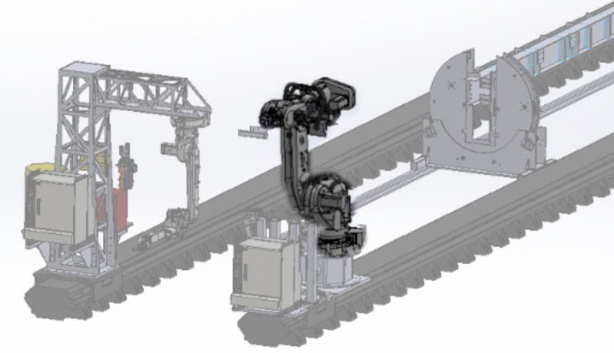

Modern manufacturing is moving rapidly toward automation that is not only efficient but also adaptable. One of the key breakthroughs in this transformation is the Eva 2.0 Welding Complex, a robotic solution designed to deliver consistent welds, minimize human risk, and streamline workflow. However, the real strength of this complex lies in its seamless integration into production lines, where it does not operate as an isolated machine but as a part of a synchronized ecosystem.

Key Benefits of Integrating Eva 2.0 into Production

When companies decide to introduce robotic welding into their workflow, the expectation is clear: improved output, lower costs, and safer operations. Yet the value of Eva 2.0 is best seen when its advantages are viewed systematically. Below are the key benefits that manufacturers experience after integration:

- Enhanced precision. Robotic welding ensures repeatable, defect-free welds with adaptive arc-sensing and seam tracking.

- Consistent quality. Automation eliminates the variability of manual welding, resulting in uniform welds across different shifts.

- Operator safety. By shielding staff from heat, sparks, and fumes, the system creates a safer workplace.

- Reduced downtime. Digital twin simulation and offline programming prepare welding routines in advance, so line changes happen faster.

- Improved productivity. A well-integrated Eva 2.0 cell can significantly raise Overall Equipment Effectiveness (OEE), contributing to measurable ROI.

Together, these factors redefine welding not as a manual bottleneck but as a streamlined, scalable process that adds value across the entire line.

Challenges and Solutions in Integration

Despite the clear benefits, integration into an existing production line is never plug-and-play. Companies face obstacles that must be identified and resolved early. Recognizing these challenges—and their solutions—helps ensure a smooth adoption curve:

- Compatibility with existing systems. Legacy machines and older software often require middleware or interface customization.

- Layout constraints. Welding cells must be carefully positioned to optimize robot reach while respecting safety standards.

- Skill gap. Operators may lack experience with robotic welding, requiring tailored training programs.

- Data connectivity. To unlock analytics and predictive maintenance, the system must be linked to factory networks.

- Change management. Employees need to see the robot as an ally, not a replacement, which requires transparent communication.

By addressing these issues proactively, manufacturers minimize disruption and accelerate the path to value creation.

Best Practices for Successful Implementation

Integrating a welding robot is not just about installing hardware—it is about embedding it into the daily rhythm of production. Companies that follow structured practices gain the most from their investment. The following steps represent a proven roadmap to success:

- Conduct a process audit. Map current workflows to identify bottlenecks where automation adds the most value.

- Leverage simulation. Use digital twin models to validate robot programs and cell layouts before deployment.

- Invest in training. Provide hands-on learning for operators and technicians to build confidence and competence.

- Plan gradual adoption. Start with one or two product lines, then scale as efficiency gains become clear.

- Integrate with inspection and logistics. Welding cells work best when linked to quality control systems and material handling robots.

These practices ensure that Eva 2.0 becomes more than a machine on the shop floor—it evolves into a cornerstone of a smarter, more agile production system.

Conclusion

Integrating the Eva 2.0 Welding Complex into a production line represents more than an upgrade in machinery—it’s a strategic step toward building a smart, connected factory. By carefully balancing technical precision with human expertise, manufacturers can achieve safer operations, higher productivity, and long-term scalability. To push the boundaries even further, the addition of Custom Software Development (https://quant-robotics.com/solutions/custom-software) can transform a standard welding complex into a tailored solution that perfectly aligns with unique production goals, ensuring every weld is not only strong but also part of a stronger business future.