Jeremy S. Cook

hackster.io

In this project, I am showing you how to build a digital laser tachometer based on Arduino for around 10$. If you need to measure rotational speed, you can just buy it or do it yourself and learn something while building it!

Laser tachometers are able to measure how fast something is rotating by sensing a reflective surface as it whizzes by. While cheap laser tachs can be had for $20 or so, if you’d rather produce your own, you can construct this model by Elite Worm with an Arduino clone, laser, and sensor for about half that cost (Figure 1). You’ll also need a 3D printer for the housing, though you could probably get creative if one’s not available.

|

|

| Рисунок 1. | Laser Tachometer on Arduino. |

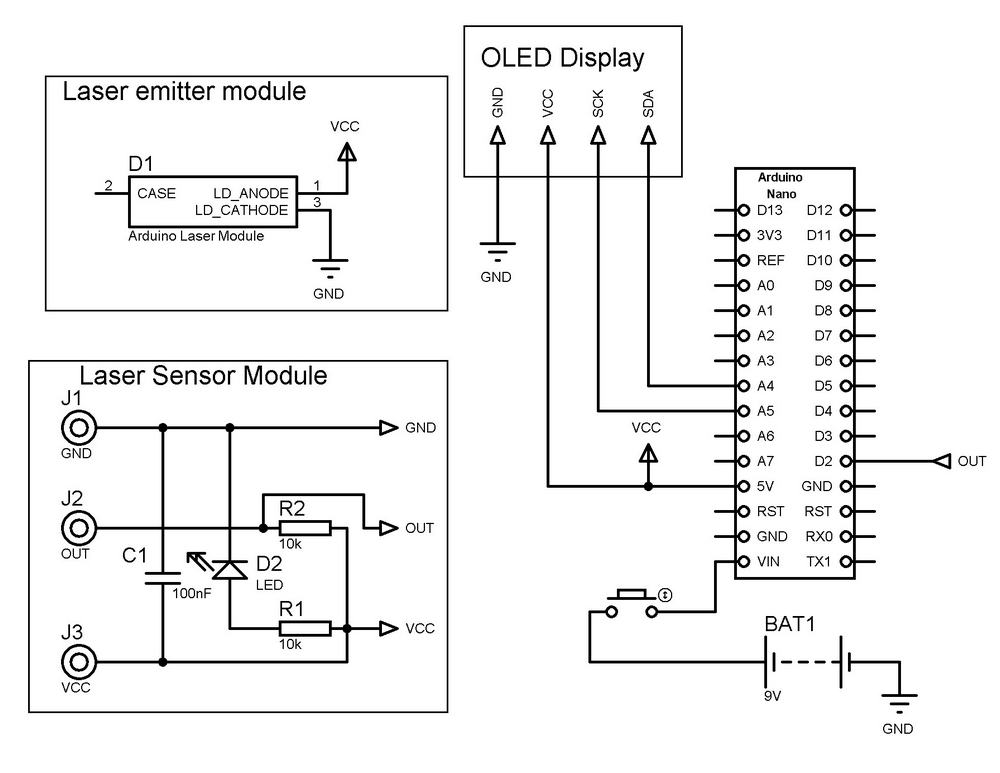

Schematic diagram (modules connecting) shown in Figure 2.

|

|

| Рисунок 2. | Laser Tachometer Schemtaic Diagram. |

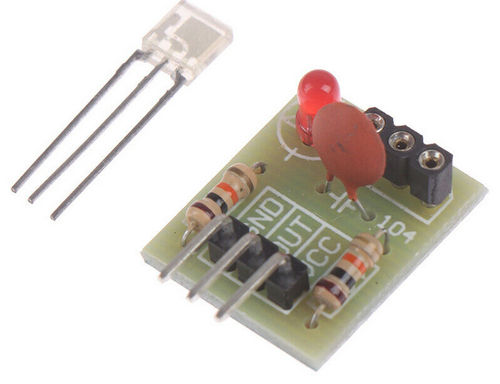

What did you need to assemble the device: Arduino Nano, 128×32’’ I2C OLED Display (Figure 5), Tactile Push Button (6×6×7 mm), Battery connector, Laser emitter module (Figure 3) with 5 V Working Voltage, Laser sensor module (Figure 4).

|

|

| Рисунок 3. | Laser Emitter module: 650 nm, 5 mW, 5 V. |

|

|

| Рисунок 4. | Laser sensor module. |

|

|

| Рисунок 5. | OLED Display module with I2C interface. |

The video below goes over the build process in some detail, which involves hooking the Arduino up to a small I2C OLED display, along with a single interface button to start measuring. A small laser diode is also soldered onto a detector PCB and attached to the Nano, allowing it to measure reflections.

As seen in the demo starting at just after 4:40 in the video below, the DIY tachometer shows roughly the same values as a commercial version, and even provides a better refresh rate.

If you’d like to make your own, code and an STL for the physical design is available on Download section. Notably, Elite Worm did a great job modeling everything in place, so you’ll be using screws instead of hot glue if you follow his mechanical design!