By Graham Prophet

EDN-Europe

This little alarm clock very nearly qualifies as a family heirloom; it has performed uncomplainingly for around 35 years, and I would not have thought to dismantle it if it had not developed a slight fault. And in the course of attending to that fault I noticed something about it that had escaped me for all the time I have known it.

The clock is branded «Metamec» – prior to venturing into the digital domain, this company sold mains-powered analogue clocks using synchronous motors. The digital clock is as simple as you could expect it to be; 12 hour display with AM/PM indication on red 7-segment LEDs, single alarm set-point, and deriving its timebase from counting 50-Hz mains cycles. An interruption to mains power, and therefore timing, is indicated by a flashing display. A particularly sophisticated feature – for the time it was manufactured – is the inclusion of a touch-panel to activate the «snooze» function.

Just lately, it would enter flashing-display mode without any mains outage having taken place and, given its long service, it seemed worthwhile fixing it. I wasn't in any doubt as to what I was going to find when I undid the retaining screws. I expected to see a pretty rudimentary linear power supply with electrolytic capacitor(s) totally dried out after all these years. My assumption was that the ripple on the DC rail had reached the point that the chip was reading the dips as a momentary power outage, and changing mode accordingly.

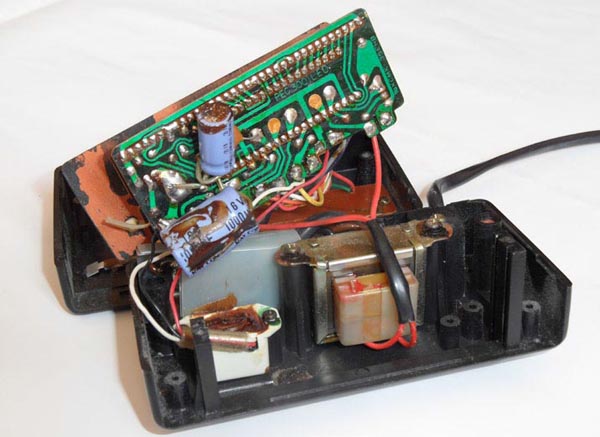

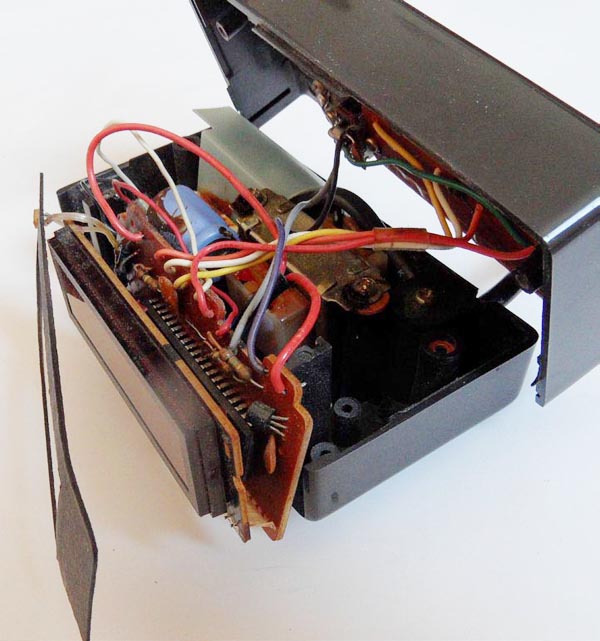

And that is exactly what I found, as you can see in picture 2; replacing the electrolytics restored normal operation, and that's the end of the repair story. It was such an open-and-shut case I didn't even bother to put a scope on it to see how bad the DC really was.

Having taken it apart, I was of course curious to find out what components had been used: it turns out to be completely standard. There is a single 40-pin dip, which is a National Semiconductor MM5387AA. Despite being long obsolete, the data sheet is still out there, archived on the web in multiple places. I had thought that by 1978 it might be nMOS, but the data sheet says it's PMOS, perhaps because the direct drivers for the LEDs were a bit easier to do in PMOS. The sheet doesn't say what process node it is built in, but purely by the date it's going to be around 5 microns – as it's PMOS, maybe still in something like 10 microns. For those who have only known the terminology of the last decade or two – yes, that's ten whole microns, 1/100th of a millimetre; if you could peer really closely at a bare die you could almost see the transistors. The data sheet also confirms that any excursion of VDD to within a small margin of the minimum value needed to retain timing data sets a latch into flashing-display mode.

The LED module – four digits in one moulding – has a part number, TLR2047, that similarly calls up a long-forgotten Toshiba data sheet, and as it has the plain upper-case «T» logo that the company used over many years, its identity is not in doubt. One reasonable conclusion to take away is that if you want longevity, using quality branded components is a good place to start.

Describing the power-supply arrangements as «rudimentary» is almost too generous; a single transformer winding (the white block with the remains of the electrolytics on it is the alarm buzzer) feeds a single diode with 220 µF hanging off it (electrically, and literally), to supply the LEDs; a second diode tapped off that line, followed by 1000 µF, feeds the IC.

The construction is entirely as you would expect and apart from the fact that there is nothing surface-mount, little has changed over three decades. The 40-pin DIP and the 4-digit, 7-segment display module is about all there is, apart from power supply and a handful of passives to handle switch inputs; there's a photocell to dim the display in low ambient light, and a single transistor plus one resistor and a ceramic capacitor is enough to pull the «snooze» pin of the module low in response to a finger touch. The two main components sit on two single-side phenolic PCBs joined by a wire preform; assembly was clearly manual and the soldering probably is also. The tired electrolytics are tacked on to the boards and hang free, definitely a structure for the bedside table and not high-g tolerant. Build quality isn't great, but has clearly been good enough for the purpose.

So what was the unexpected and previously un-noticed discovery that prompted me to write this account? On a label on the underside of the case are the words, «Made for Metamec by Samsung, Korea». In 1978, few people in the west had ever heard of Samsung; probably not many people in the UK could even have placed a pin in the map and correctly located Korea. The only Asian manufacturing identities that most British purchasers would have recognized would have been «Made in Japan» or «Made in Hong Kong»; in China, it was only two years since the death of Mao Zedong: the Cultural Revolution was barely over and the idea that China would become the default low-cost manufacturer for the Western world would have seemed absurd.

Samsung was long established as a leading chaebol (diversified industrial conglomerate) in Korea but in the late 1970s Samsung Electronics was a comparatively recent offshoot and even the company's entry into semiconductors and the DRAM market still lay some years in the future.

Here, therefore, we find the enterprise that would become one of the world's premier consumer-technology brands, developing a new business with what must have been small-volume contract assembly work. This was also largely before the days of freight containerisation: shipping costs were, relatively, far greater than we have today so it seems a reasonable guess that Samsung was prepared to operate on thin margins to penetrate this new sector.