A homing sensor is a device used in certain machines to detect a fixed reference point, allowing the machine to determine its exact starting position. When powered on, the machine moves until it triggers the sensor, so it can accurately track movement from that point onward. It’s essential for precision and repeatability in automated motion systems.

Selecting the right homing sensor can have a big impact on accuracy, dependability, and overall cost. Here is a quick rundown of the three main types (Figure 1):

|

|

| Figure 1. | Magnetic, mechanical, and optical homing sensors are available in standard configurations. |

Mechanical homing sensors: These operate through contact-direct switches or levers to determine position.

- Advantages: Straightforward, budget-friendly, and easy to install.

- Drawbacks: Prone to wear over time, slower to respond, and less accurate.

Magnetic homing sensors: Relying on magnetic fields, often via Hall effect sensors, these do not require physical contact.

- Advantages: Long-lasting, effective in harsh environments, and maintenance-free.

- Drawbacks: Can be affected by magnetic interference and usually offer slightly less resolution than optical sensors.

Optical homing sensors: These use infrared light paired with slotted discs or reflective surfaces for detection.

- Advantages: Extremely precise, quick response time, and no mechanical degradation.

- Drawbacks: Sensitive to dust and misalignment and typically come at a higher cost.

In clean, high-precision applications like 3D printers or CNC machines, optical sensors shine. For more demanding or industrial environments, magnetic sensors often strike the right balance. And if simplicity and low cost are top priorities, mechanical sensors remain a solid choice.

The following parts of this post detail the design framework of a universal homing sensor adapter module.

We will start with a clean, simplified schematic of the universal homing sensor adapter module shown in Figure 2. Designed for broad compatibility, it accepts logic-level inputs – including both CMOS and TTL-compatible signals – from nearly any homing sensor head, whether it’s mechanical, magnetic, or optical, making it a flexible choice for diverse applications.

|

|

| Figure 2. | A minimalistic design highlights the inherent simplicity of constructing a universal homing sensor module. |

The circuit is simple, economical, and built using easily sourced, budget-friendly components. True to form, the onboard test button (SW1) mirrors the function of a mechanical homing sensor, offering a convenient stand-in for setup and troubleshooting tasks.

The 74LVC1G07 (IC1) is a single buffer with an open-drain output. Its inputs accept signals from both 3.3 V and 5 V devices, enabling seamless voltage translation in mixed-signal environments. Schmitt-trigger action at all inputs ensures reliable operation even with slow input rise and fall times.

Optional flair: LED1 is not strictly necessary, but it offers a helpful visual cue. I tested the setup with a red LED and a 1-KΩ resistor (R3) – simple, effective, and reassuringly responsive.

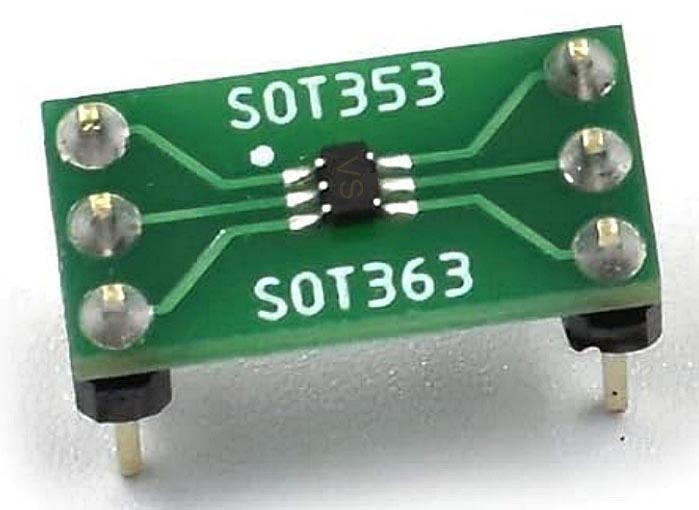

As usual, I whipped up a quick-and-dirty breadboard prototype using an SMD adapter PCB (SOT-353 to DIP-6) to host the core chip (Figure 3). I have skipped the prototype photo for now – there is only a tiny chip in play, and the breadboard layout does not offer much visual clarity anyway.

|

|

| Figure 3. | A good SMD adapter PCB gives even the tiniest chip time to shine. |

Just before the setup reaches its close, note that machine homing involves moving an axis toward its designated homing sensor – a specific physical location where a sensor or switch is installed. When the axis reaches this point, the controller uses it as a reference to accurately determine the axis position. For reliable operation, it’s essential that the homing sensor is mounted precisely in its intended location on the machine.

While wrapping up, here are a few additional design pointers for those exploring alternative options, since we have only touched on a straightforward approach so far.

Let’s take a closer look at a few randomly picked additional components and devices that may be better suited for the homing task:

- SN74LVC1G16: Inverting buffer featuring Schmitt-trigger input and open-drain output; ideal for signal conditioning and noise immunity.

- SN74HCS05: Hex inverter with Schmitt-trigger inputs and open-drain outputs; useful for multi-channel logic interfacing.

- TCST1103/1202/1300: Transmissive optical sensor with phototransistor output; ideal for applications that require position sensing or the detection of an object’s presence or absence.

- TCRT5000: Reflective optical sensor; ideal for close-proximity detection.

- MLX75305: Light-to-voltage sensor (EyeC series); converts ambient light into a proportional voltage signal, suitable for optical detection.

- OPBxxxx Series: Photologic slotted optical switches; designed for precise object detection and position sensing in automation setups.

Moreover, compact inductive proximity sensors like the Omron E2B-M18KN16-M1-B1 (Figure 4) are often used as homing sensors to detect metal targets – typically a machine part or actuator – at a fixed reference point. Their non-contact operation ensures reliable, repeatable positioning with minimal wear, ideal for robotic arms, linear actuators, and CNC machines.

|

|

| Figure 4. | The Omron E2B-M18KN16-M1-B1 inductive proximity sensor supports homing applications by detecting metal targets at fixed reference points. That enables precise, contactless positioning in industrial setups. |