Bin Wu, Analog Devices

Design Note 572

Introduction

The LT8672 is an active rectifier controller that (along with a MOSFET) provides reverse current protection and rectification for power supplies in automotive environments. This job is traditionally taken on by a Schottky diode, over which the LT8672’s active protection has a number of advantages:

- Minimal power dissipation

- Small, predictable, regulated 20 mV voltage drop

The LT8672 also includes a number of features to satisfy supply rail requirements in automotive environments:

- Reverse input protection to –40 V

- Wide input operation range: 3 V to 42 V

- Ultrafast transient response:

- Rectifies 6 VP-P up to 50 kHz

- Rectifies 2 VP-P up to 100 kHz

- Integrated boost regulator for the FET driver performs better than charge pump devices

Figure 1 shows a complete protection solution.

|

||

| Figure 1. | LT8672 Active Rectification/Reverse Protection Solution. | |

Fast Response for Input Ripple Rectification

Automotive standards – ISO 16750 or LV124 – specify that automotive electronic control units (ECUs) may face a supply with a superimposed AC ripple of up to 6VP-P at up to 30 kHz. The LT8672's gate driver that controls the external MOSFET is strong enough to handle ripple frequencies of up to 100 kHz, which minimizes reverse current. An example of such an AC ripple rectification is shown in Figure 2.

|

||

| Figure 2. | Rectification of Input Ripple. | |

Low Power Dissipation Compared with a Schottky Diode

|

||

| Figure 3. | System Configuration (a) LT8672 Controlled System (b) Schottky Diode System. |

|

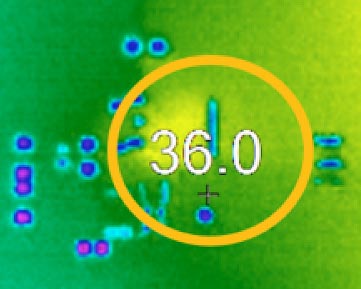

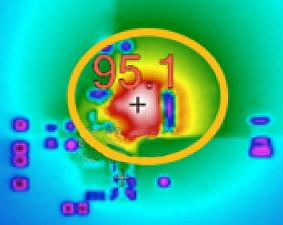

The performance of the LT8672 (using the IPD100N06S4-03 as external MOSFET) can be compared to a Schottky diode (CSHD10-45L) with the setup shown in Figure 3. Here, a 12 V power supply at the input emulates the automotive voltage supply, and the output is loaded with a constant current of 10 A. Thermal performance for both solutions at steady state is shown in Figure 4. Without cooling, the thermal performance of the LT8672 solution is far superior, reaching a peak temperature of only 36 °C, while the Schottky diode solution reaches a much higher 95.1 °C.

|

||||||

| Figure 4. | Thermal Performance Comparison (a) LT8672 Controlled System (b) Schottky Diode System. |

|||||

Extra Low Input Voltage Operation Capability

Automotive mission critical circuitry must be able to operate during cold crank conditions, when the car battery voltage can collapse to 3.2 V. With this in mind, many automotive grade electronics are designed to operate down to 3 V input. A Schottky’s variable forward voltage drop can present a problem during cold crank, where this drop produces a downstream voltage of 2.5 V to 3 V, too low for some systems to operate. In contrast, a LT8672 solution guarantees the required 3 V due to its regulated 20 mV voltage drop, allowing easier circuit design and improved system robustness.

|

||

| Figure 5. | System Configuration for Cold Crank Test. | |

Figure 5 shows a comparative cold crank test setup using an LT8650S step-down converter as the downstream test system. The LT8650S output is set to 1.8 V at a constant load of 4 A, and its minimum input operating requirement is 3 V. The results are shown in Figure 6.

|

||

| Figure 6. | System Voltage Comparison Under “Cold Crank” (a) LT8672 Controlled System (b) Schottky Diode System. |

|

When VBATT drops to 3.2 V, the LT8672 controlled system (a) maintains VIN > 3 V, allowing the LT8650S to keep its output VSYS stable at 1.8 V, while in the Schottky diode system (b) the input voltage VIN of the LT8650S drops below its minimum operating voltage, preventing it from maintaining 1.8 V at its output VSYS.

Integrated Boost Regulator

Many alternative active rectifier controllers use a charge pump to power the gate driver. These solutions often cannot provide strong gate charging current and a regulated output voltage, limiting the frequency range and performance of continuous rectification. The LT8672’s integrated boost regulator provides a tightly regulated gate driver voltage with strong gate driver current.

Conclusion

The LT8672 is able to rectify high frequency AC ripple on automotive supplies. It uses an integrated boost regulator to drive a MOSFET for ultrafast response during continuous rectification, an improvement over charge pump solutions. It provides rectification and reverse input protection with low power dissipation and an ultra-wide operational range (desirable for cold crank) in a tiny 10-lead MSOP package.