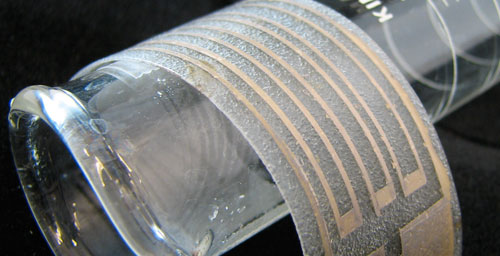

University of Illinois materials scientists have developed a new reactive silver ink for printing high-performance electronics on ubiquitous, low-cost materials such as flexible plastic, paper or fabric substrates.

Electronics printed on low-cost, flexible materials hold promise for antennas, batteries, sensors, solar energy, wearable devices and more. Most conductive inks rely on tiny metal particles suspended in the ink. The new ink is a transparent solution of silver acetate and ammonia. The silver remains dissolved in the solution until it is printed, and the liquid evaporates, yielding conductive features.

The reactive ink has several advantages over particle-based inks. It is much faster to make: A batch takes minutes to mix, according to Walker, whereas particle-based inks take several hours and multiple steps to prepare. The ink also is stable for several weeks.

The reactive silver ink also can print through 100-nanometer nozzles, an order of magnitude smaller than particle-based inks, an important feature for printed microelectronics. Moreover, the ink’s low viscosity makes it suitable for inkjet printing, direct ink writing or airbrush spraying over large areas.

The reactive silver ink boasts yet one more key advantage: a low processing temperature. Metallic inks typically need to be heated to achieve bulk conductivity through a process called annealing. The annealing temperatures for many particle-based inks are too high for many inexpensive plastics or paper. By contrast, the reactive silver ink exhibits an electrical conductivity approaching that of pure silver upon annealing at 90 degrees Celsius.