Newly developed radio-frequency identification (RFID) technology could usher in the era of checkout line-free shopping. The inexpensive, printable transmitter can be invisibly embedded in packaging offering the possibility of customers walking a cartload of groceries or other goods past a scanner that would read all the items at once, total them up and charge the customer’s account while adjusting the store’s inventory. More advanced versions could even collect all the information about the contents of a store in an instant, letting a retailer know where every package is at any time.

Researchers from Rice University working in collaboration with a team led by Gyou-jin Cho at Sunchon National University in Korea, developed the new technology which is based on a carbon-nanotube-infused ink for ink-jet printers first developed in the Rice lab of James Tour. The ink is used to make thin-film transistors, a key element in radio-frequency identification (RFID) tags that can be printed on paper or plastic.

“We are going to a society where RFID is a key player,” said Cho, a professor of printed electronics engineering at Sunchon, who expects the technology to mature in five years. Cho and his team are developing the electronics as well as the roll-to-roll printing process that, he said, will bring the cost of printing the tags down to a penny apiece and make them ubiquitous.

RFID tags are almost everywhere already. They are being used to identify and track everything from farm animals to shipping containers and passports to library books. But to date RFID tags have been largely silicon-based. Paper or plastic tags printed as part of a package would cut costs dramatically and the roll-to-roll technique, which uses a gravure process rather than inkjet printers, could replace the barcodes that currently appear on just about everything we buy.

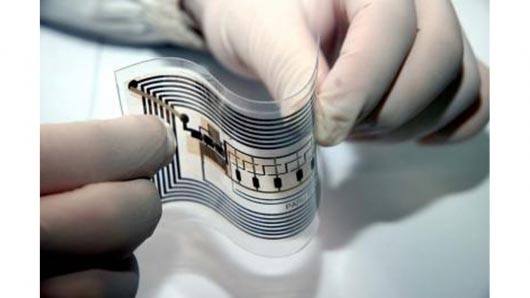

The researchers have already developed a three-step process to print one-bit tags, including the antenna, electrodes and dielectric layers on plastic foil. Work is underway on 16-bit tags that would hold a more practical amount of information and be printable on paper as well.

The researchers say the RFIDs are practical because they are passive. The tags power up when hit by radio waves at the right frequency and return the information they contain. “If there’s no power source, there’s no lifetime limit. When they receive the RF signal, they emit,” Tour said.

There are several hurdles to commercialization. First, the device must be reduced to the size of a bar code, about a third the size of the current device. Second, its range must increase.

“Right now, the emitter has to be pretty close to the tags, but it’s getting farther all the time,” he said. “The practical distance to have it ring up all the items in your shopping cart is a meter. But the ultimate would be to signal and get immediate response back from every item in your store – what’s on the shelves, their dates, everything.

“At 300 meters, you’re set – you have real-time information on every item in a warehouse. If something falls behind a shelf, you know about it. If a product is about to expire, you know to move it to the front – or to the bargain bin.”

Tour allayed concerns about the fate of nanotubes in packaging. “The amount of nanotubes in an RFID tag is probably less than a picogram. That means you can produce one trillion of them from a gram of nanotubes – a miniscule amount. Our HiPco reactor produces a gram of nanotubes an hour, and that would be enough to handle every item in every Walmart.

“In fact, more nanotubes occur naturally in the environment, so it’s not even fair to say the risk is minimal. It’s infinitesimal.”