Janine Love

EDN

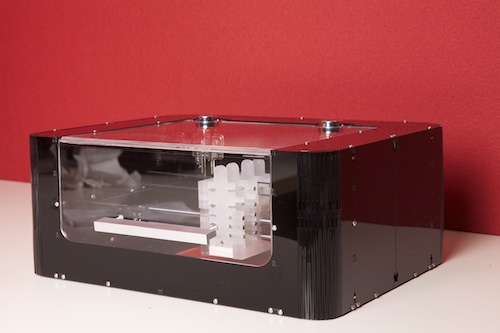

Today, there is a printer called The EX¹ launching on Kickstarter. The inventors, three students who formed Cartesian Co. , demonstrate how you can quickly create circuit boards on paper, plastic, glass, wood, ceramic, silicone, and fabric. The printer is priced at $1,199 and promises to simplify prototyping. Delivery is expected for early 2014. In the five minutes I was on their Kickstarter page this morning, the money raised kept ratcheting up, and I have no doubt they will rapidly make their $30,000 goal.

The EX¹ has two inkjet cartridges and prints onto the substrate much like a desktop inkjet printer would. However, instead of ink, the EX¹ lays down two chemicals that produce silver nano particles, leaving a silver image on the substrate.

I had some questions for the founders, Ariel Briner, Isabella Stephens, and John Scott. Both still students at the University of Queensland, Ariel Briner is in the process of completing his bachelor's degree in electrical and aerospace engineering and Isabella Stephens is currently studying for her dual degree of software engineering and commerce. John Scott has earned his bachelor’s degree in mechanical and aerospace engineering from the University of Queensland. Given that they are in Australia and we were dealing with major time zone issues, Briner, who serves as head of electrical design was kind enough to answer my questions via email.

|

| Left to right, Isabella, John and Ariel |

Janine Love: Tell me a bit about the history of your project/company and how the three co-founders came together?

Ariel Briner: I had the idea for this printer several years ago when trying to make a PCB at home for a university project. At the time, I tried to build a version of what the printer has become, but failed because I was trying to do it on my own. Now, a couple of years later I have a team, and over the last year we’ve managed to successfully bring my original idea to reality. I have two co-founders (John and Isabella). John and I have been friends since high school, and I met Bella in a programming lecture at the University of Queensland.

|

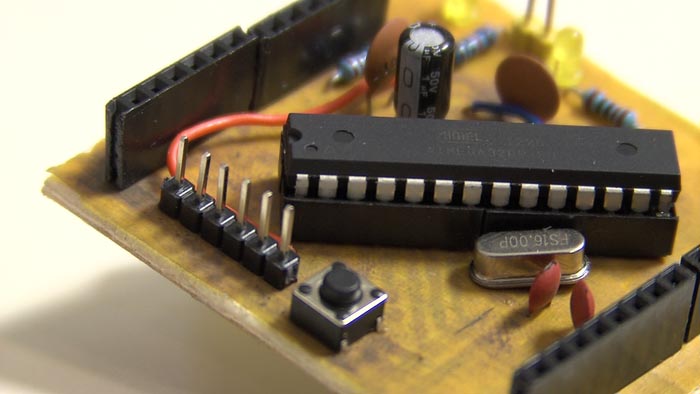

| Arduino compatible microcontroller printed on kapton and wood |

Love: How long did it take from concept to working prototype for this printer?

Briner: From the very first time I had the idea it’s been four years. But, since working on the idea with my team, it’s only taken a year to succeed where I previously failed.

|

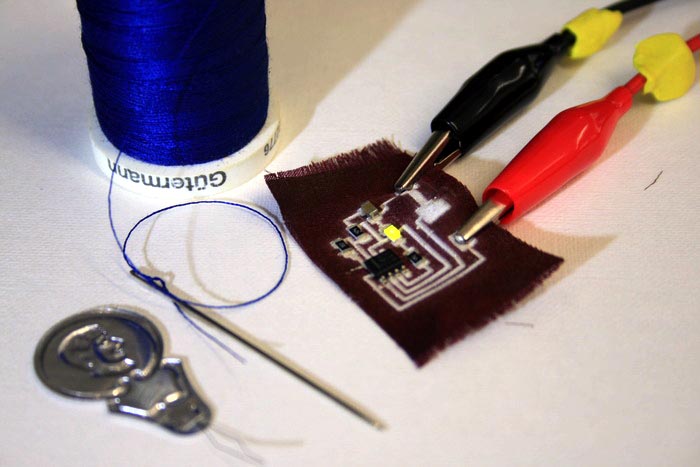

| Flashing LED circuit printed on synthetic fabric |

Love: What were the major technical challenges?

Briner: There were two major technical problems, the first and worst of which being the sheer number of possible solutions to the PCB rapid prototyping problem. I always knew that an inkjet solution was going to be the best. Even then, there is the possibility of printing a resist then acid etching, printing with existing commercial inks, or our preferred method of a two-ink silver precipitate system. Picking the wrong one of these methods is what stopped me the first time.

The second major problem was the inkjet cartridge, including deciding whether or not to manufacture it ourselves and how to control it.

|

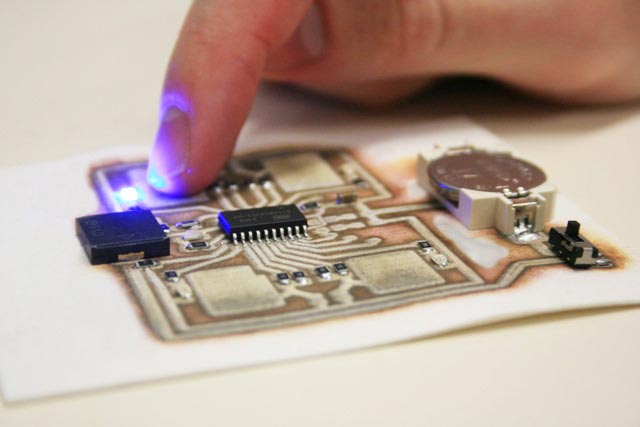

| Touch sensitive "Simon Says" game printed on paper |

Love: How did you overcome them?

Briner: Overcoming the first problem was easy. I had already tried and failed at one technique, leaving only two to choose from. Solving the inkjet cartridge problem was a fun challenge. There is very little information available on how inkjet cartridges work and how to use them. We relied heavily on what information was out there, and with a little tinkering we managed to get it working better than even we hoped.

|

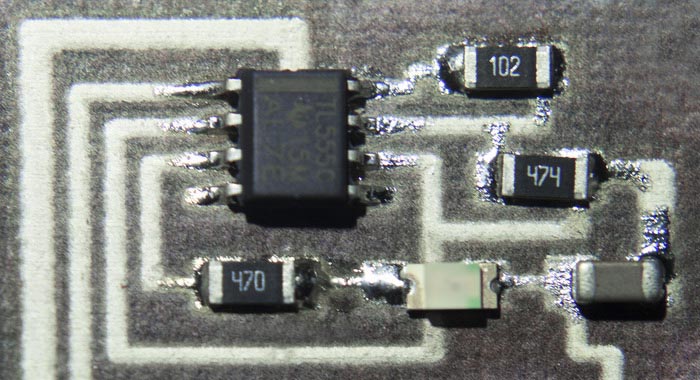

| Close up of a surface mount circuit printed straight onto paper |

Love: What are the limitations of using silver nano particles? How fast a circuit can they support?

Briner: Silver nano-particles are great, we’ve been able to get traces to continue working when bent, exposed to water, and soldered. Honestly, we haven’t yet found the limitations of them. Obviously, the limiting factor in circuit speed is parasitic capacitance, which varies considerably. There are many factors which affect this, not all of which we have had the time to fully explore. We have tested up to 20MHz micro controllers and not found the limit yet. We have no doubt that higher speeds will be attainable.

|

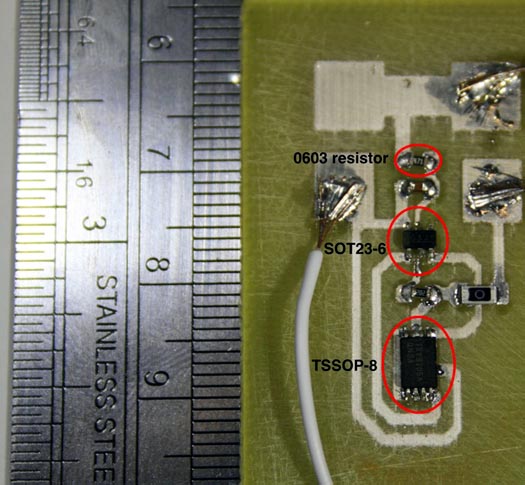

| LiPo protection circuit printed on FR4 showing the fine resolution possible |

Love: What's the roadmap look like? How will you enhance this in the next-generation?

Briner: Rapid prototyping (in particular 3D printing) was a huge inspiration for the printer. I always think how different the world would be if everyone had the ability to make circuits at home as easily as 3D printing. Things change so fast in this space it’s really difficult to say what the future holds. We have a million ideas but only two hands. That said we do have big dreams for a complete circuit fab on your desk.

Printer specs:

- Print Area: 17.5 cm × 8 cm

- Printer Size: 41.2 cm Wide × 31.2 cm Deep × 16.6 cm High

- Printer Weight: About 6kg with full cartridges