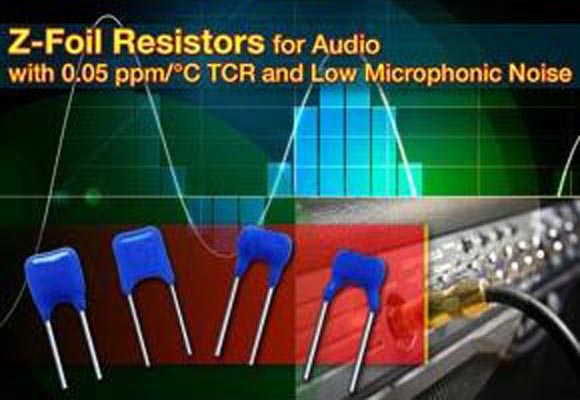

Vishay Precision Group announced that its Vishay Foil Resistors brand (VFR) has introduced a new series of ultra-high-precision, through-hole Z-Foil resistors designed to provide low noise and low inductance/capacitance for high-end audio applications requiring distortion-free properties. The conformally coated, low-profile AUR series devices feature low TCR down to 0.05 ppm/°C nominal from 0°C to +60°C, +25°C ref, tolerances down to ±0.01%, and load-life stability to ±0.01% after 2,000 hours at +70 °C.

In high-end audio equipment, careful selection of resistors is one of the best ways to minimize noise and distortion in the signal path. The typical audio amplifier consists of a voltage preamplifier and power amplifier. The voltage preamplifier deals with low-level signals, making the intrinsic noise of resistors critical, while the power amplifier requires high linearity of amplification and minimal dynamic distortion. Bulk Metal® Foil AUR devices meet both of these needs thanks to their cold-rolled metal alloy foil. Their construction eliminates any current noise in the element itself, and provides the linearity that preserves signal integrity with no clipping or roll-off at signal extremes.

AUR devices also feature a special "noise-free" design, with special in-house stabilization, providing an additional dimension for reducing signal distortion and increasing clarity in signal processing. Furthermore, the current in adjacent current-carrying paths runs in opposing directions, canceling the paths' parasitic inductance. Path-to-path capacitances are connected in series, minimizing the parasitic capacitance of the resistor.

|

|

| Trimming to Values (conceptual illustration). |

"Many users of precision audio equipment suffer needlessly from unexplained instabilities and drifts due to noise effects and harmonic distortion. They resign themselves to making constant adjustments and troubleshooting, but in fact these can be avoided," said Yuval Hernik, senior director of application engineering for VFR. "Instability is often traceable to a few supposedly fixed resistors, which are not really fixed at all. If these resistors would only retain their original values, there would be no need for costly controls and other compensating circuitry. That’s why Bulk Metal Z-Foil resistors are the only devices for applications such as these."

“Microphonic noise is a parasitic effect mostly associated with surface-mounted resistors. The plane of the mounted resistive element is parallel to the board, by which vibrational movement induces spurious signals in much the same way as a diaphragm in a speaker system," added Hernik. "The horizontal resistor element produces the same microphonic effect, whether caused by physical vibration of the board or by strong sonic waves impinging on it.”

The AUR series offers a resistance range from 5 Ω to 120 kΩ. Any conceivable ohmic value within this range, to six digits, is available with no additional cost or lead time effect. The resistors feature rated power to 300 mW at +70 °C, a maximum working voltage of 300 V, a rise time of 1 ns with effectively no ringing, current noise of < 0.010 √μV/V of applied voltage (< –40 dB), a thermal stabilization time of < 1 s (within 10 ppm of steady state value), and a voltage coefficient of < 0.1 ppm/V.

"Particularly in high-precision audio applications, the best resistor choice is often a through-hole device that is specifically designed to provide higher resistance values, higher power, tighter tolerances, and better long-term stability, while requiring less board space and allowing the clean-up of solvents and resins," added Hernik. "Through-hole devices achieve better stability because they are not subjected to thermo-mechanical stresses from the PCB. And unlike other through-hole resistors, the AUR devices require no added height for stress-relieving bends in the leads, as they feature built-in stress relief."

Samples and production quantities of the AUR series are available now, with lead times of two weeks for samples, and eight weeks for standard orders.