New Superconducting Materials Improve the Efficiency and Reliability of Grids and Systems

For the first time, a superconducting current limiter based on YBCO strip conductors has now been installed at a power plant. At the Boxberg power plant of Vattenfall, the current limiter protects the grid for own consumption that is designed for 12 000 volts and 800 amperes against damage due to short circuits and voltage peaks. The new technology co-developed by Karlsruhe Institute of Technology and made by Nexans SuperConductors enhances the safety of the grid and may help reduce the investment costs of plants.

|

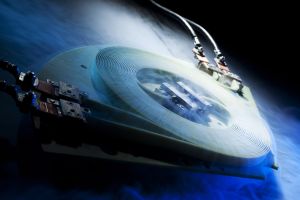

| Superconducting coils are cooled with liquid nitrogen and have zero resistance to current flow. (Photo: Martin Lober, KIT) |

Superconducting current limiters work reversibly. In case of current peaks after short circuits in the grid, no components are destroyed. The limiter automatically returns to the normal state of operation after a few seconds only. Consequently, the power failure is much shorter than in case of conventional current limiters, such as household fuses, whose components are destroyed and have to be replaced with a high time and cost expenditure.

Reliable, compact current limiters enhance the operation stability of power grids and allow for a simplification of the grid structure. As they are protected against current peaks, decentralized energy generators, such as wind and solar systems, can be integrated much better in grids. Expensive components in the existing grid are protected efficiently, components in future grids can be designed for smaller peak currents, and transformers will no longer be necessary. Investment costs of power plants and grids will be reduced. Moreover, superconducting current limiters on the basis of YBCO can also be applied in high-voltage grids of more than 100 kilovolts for better protection against power failures in the future.

YBCO stands for the constituents of the superconductor: Yttrium, barium, copper, and oxygen. An YBCO crystal layer of about 1 micrometer in thickness is grown directly on a stainless steel strip of a few millimeters in width that gives the ceramics the necessary stability. Below a temperature of 90° Kelvin or minus 183° Celsius, the material becomes superconductive. However, superconductivity collapses abruptly when the current in the conductor exceeds the design limits. This effect is used by the current limiter. In case of current peaks in the grid, the superconductor loses its conductivity within fractions of a second and the current will flow through the stainless steel strip only, which has a much higher resistance and, thus, limits the current. The heat arising is removed by the cooling system of the superconductor. A few seconds after the short circuit, it is returned to normal operation in the superconducting state.

The superconducting current limiter was developed in the past two years under the ENSYSTROB project. The project partners are Karlsruhe Institute of Technology, Nexans SuperConductors, TU Dortmund, and BTU Cottbus. The project was funded with about EUR 1.3 million by the Federal Ministry of Economics. The results of the project are of high relevance, as the functionality of current limitation may be integrated in superconducting transformers and energy cables in the future.