Full disclosure: These PCBs were provided by PCBWay

Obviously I’m going to take some experiments to test these boards and take a look at advantages and disadvantages of these PCBs.

Begin with some images:

PCBWay PCB Prototyping Service:

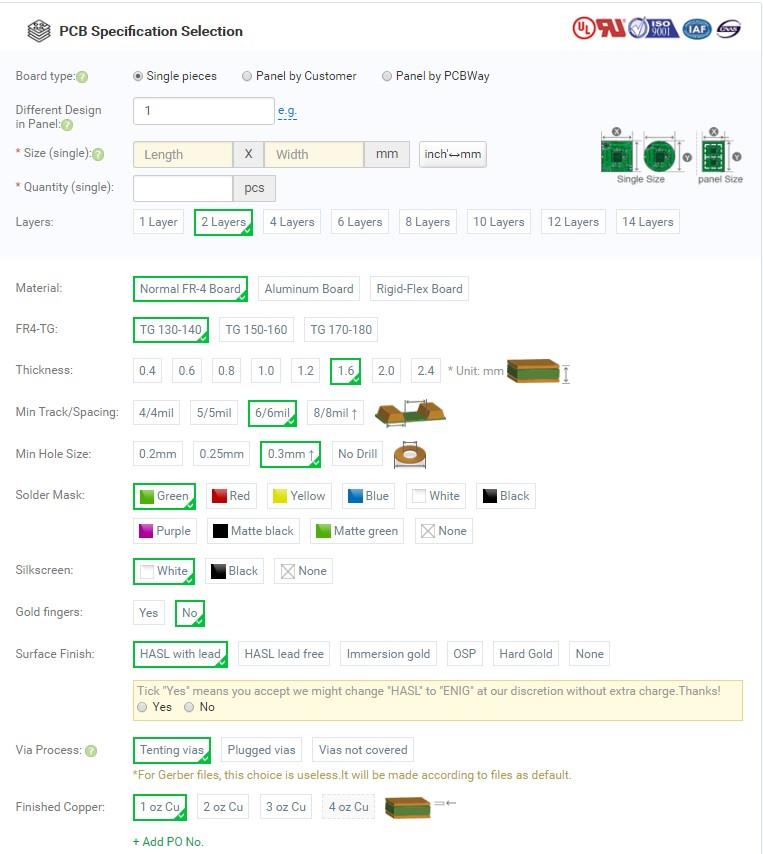

The price of PCBWays’ prototyping service becomes as low as $5/10pcs for max 100 × 100 mm size, FR4 double side custom PCB. As the same with many Chinese PCB manufacturers you need to input the parameters.

A choice of nine solder mask colors, white or black silkscreen and an array of thicknesses (0.6 mm, 0.8 mm, 1.0 mm, 1.2 mm and 1.6 mm; thicker and thinner PCBs are available but the price will be a bit higher). The default minimum track/ spacing is 6/6 mil (0.1524 mm), but it would be better to choose the tolerances to 4/4 mil and can also be ordered at a premium. The default minimum hole size is 0.3 mm and it is similar with the default minimum track/ spacing which means that it better spec is available but its price would be higher according to your requirements.

Take a comprehensive consideration of the price, the quality and the delivery time, it is not hard to draw a conclusion that PCBWay is quite competitive compared to other companies.

Order Process:

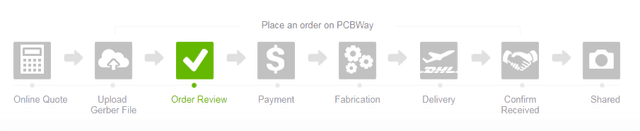

The order process of PCBWay is a little different from other companies’ because PCBWay allows their engineers to take a look at PCB designs before customers’ payment, which can reduce the unnecessary mistakes and increase the work efficiency so that amost no errors would occur after the customers submit the Gerber files. Of course, both the engineers and the customers do not expect any problems. Most functions of PCBWay background systems are automated.

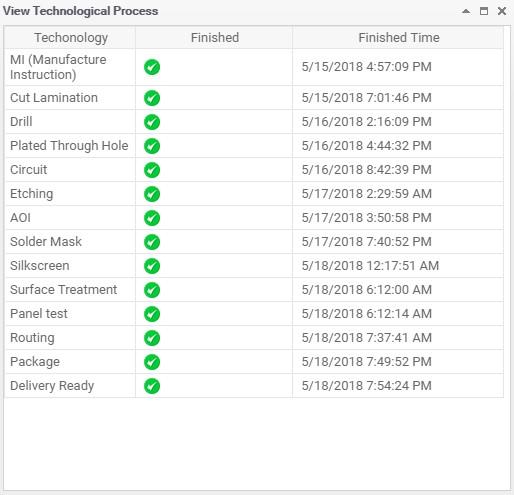

The most excellent part of PCBWay’s background system is that it allows customers to track the whole detailed progress of their boards which means they can see every step of the production process. For example, I uploaded the Gerber files on 15th May and I can track my order progress online whenever. For small runs like mine, it might not be so crucial but if you were doing a large project with panels of many boards, it would definitely be handy.

According to the picture above, we can see they started to manufacture on 15th May and completed everything on 18th May and after packaging, they shipped the boards to me on 18th May and provided me with a tracking number. It took them only three days to complete the whole process, which gives me a sense of how productive they were.

Here’s a summary of the timeline:

- 15th: Gerber files submission

- 15th: start of PCB manufacturing

- 18th: boards completed

- 18th: boards shipped (via DHL to US)

- 21th: boards received

Delivery

Nobody wants to wait for standard China Post unless you really are on a shoestring budget (I’ve had some packages take 10 days to arrive, others 30 days, some didn’t arrive at all…). I generally prefer to choose DHL than choosing Fedex because its price is a bit cheaper than Fedex’s, besides they have the comparable delivery time. Such as selecting DHL (+$16) quoted 3-5 days delivery to the US.

3 days delivery to the US even including customs clearance! Well worth the extra money, no qualms whatsoever. The boards were nicely packaged.

PCB build quality

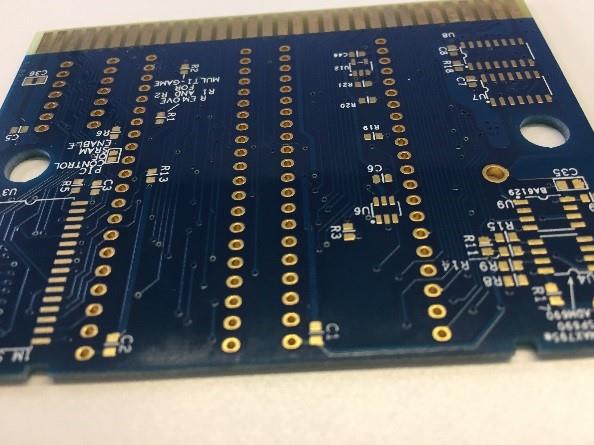

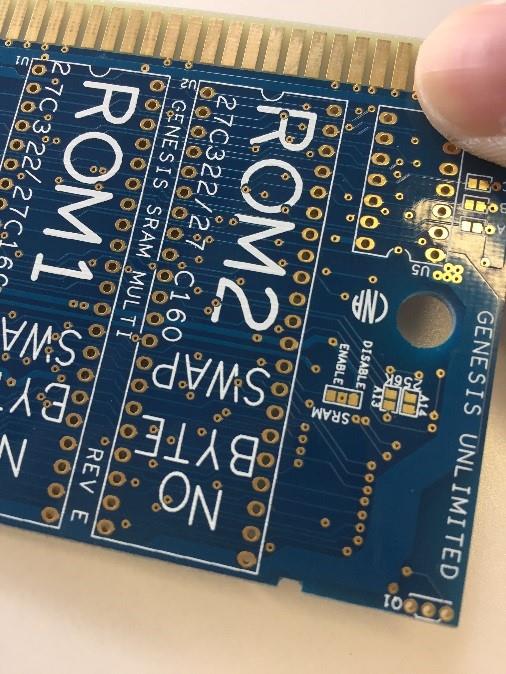

The first impressions are good of the boards after unpacked and unwrapped and the solder masks are bright and the silkscreens are reasonably legible.

[Min Track/Spacing: 6/6 mil, Min Hole Size: 0.3 mm, Blue Solder Mask, White Silkscreen]

Traces/vias

Copper and surface finish

Immersion gold looks good, nice and shiny. Haven’t done any resistance testing but I am fairly confident because I actually got 1 oz copper.

Silkscreen

The white silkscreen is quite legible, no misaligned or badly offset silkscreen. Compared to other PCB manufacturers, the silkscreens of PCBWay’s boards are actually better. As with many Chinese PCB manufacturers an internal tracking code is placed on the silkscreen layer, fortunately they found a spot under an inductor. No unsightly codes on finished PCB, good stuff.

Solder Mask

They also offer both matte black & matte green colors. As for me, I haven’t seen matte colors being offered from other PCB manufacturer so far. This time the solder mask color I tried is blue.

The solder mask is brightly colored and applied nicely.

Drill

Drills were nicely centered and no distinguishable offset, which means they made it properly to their own specified minimum clearances.

Conclusion

Well, PCBWay generally makes decent PCBs. Their prototype PCBs for hobbyists (like myself) are very wonderful. If you are looking for such kinds of PCBs with a matte black or matte green solder mask, or if you need a fast turnaround time, I would recommend you to give PCBWay a try.