Introduction

Every electronic device you can consider containing a PCB is still the best and most reliable way of connecting electronics components. The PCB stands for Printed Circuit Board, on which electronic components are soldered on pads connected by conductive lines. It is still called printed, but the technology goes beyond the printing process, where multiple steps are equally important. PCB manufacturing technology continues to evolve since requirements of miniaturization, reliability, and flexibility grow. Each PCB is an art piece, which has to work as designed and look good. PCB can have a different shape, color, base materials, and even be flexible. PCB manufacturers must adapt to new trends and offer the best services the technology can offer.

Success Story of PCBWay

PCBWay is a Chinese-based PCB manufacturing company. They offer a broad spectrum of PCB prototyping, assembly, design, and CNC/3D printing services. They manufacture more than 2100 PCBs daily and ship worldwide. PCBWay has grown into huge facilities having over 520 staff members over 5+ factories. By investing in new equipment and quality control, and user support, they can provide top-notch services at very competitive prices. Many other PCB manufacturers also offer excellent services in the same price range, but many aspects make PCBWay stand out. The main is a great website, a broad spectrum of services and technologies, and last, but not least – strong community support.

Friendly website

PCB Website is very well designed and convenient from many points of view. The front page clearly states what services they are offering, how much they cost, and how they work without cluttering unnecessary information. They choose to be open with customers by providing their current statistics of orders. On the first page, they even offer the latest orders with progress information.

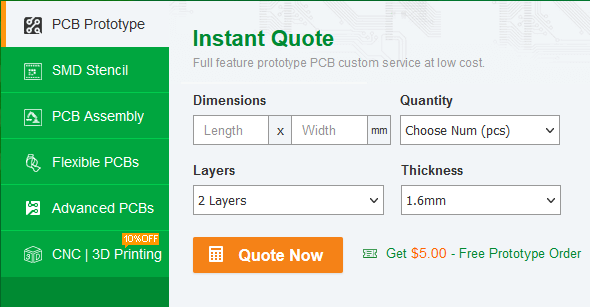

You can see the most common PCBs, along with introductory pricing depending on quota and some other parameters. You can roughly estimate how much it would cost to order 100 pcs of 2-layer PCBs or 500 aluminum boards. Such provided information means that PCBWay cares about its customers and tries to make fair and honest services.

It is easy to navigate the website as it is very intuitive and well structured. Each service has its place on the website but is still easily accessible from the main webpage. The instant quote form has it all here. Once you select the service, you are direct to a more detailed ordering form. You can select any option you want and instantly get an estimated price.

PCBWay is a company, which offers services globally, and they are trying their best to make things easier for everyone. Their main ordering page is English, and this is where the majority of orders come. Additionally, they also support Russian, Spanish, French, and Japanese websites. Professional translation adapts the website in terms of the language and the culture of the target audience.

The high-quality services

PCBWay is offering everything you need from start to finish of your electronics project. PCB Prototyping is one of the most common services they offer. There is no significant limit to what shape, size, and complexity of PCB you can order. You can tweak many PCB parameters to select different base materials, their thicknesses, the number of layers, colors of silkscreen and solder mask, surface finish. The primary base materials you can choose are:

- An advanced Rigid PCB. These are high-tech and quality boards based on /HDI/Rogers/High-Tg technologies usually purposed for high-frequency electronics, automotive, and other particular purposes. If you choose advanced panels, you may require a higher level of expertise in the area.

- Aluminum PCBs. You can select two types of aluminum PCBs – central and base core. The choice may depend on desired power dissipation properties and mechanical stability of a material.

- Copper PCBs. An aluminum base can be substituted with copper for better thermal performance and other specific properties also with higher costs.

- Flexible PCB. These types of PCBs can be used in nonstandard type portable devices or miniature electronics. You can squeeze flexible PCBs into tight spaces, bend, and wrap to eliminate enclosure constraints. Typical electronic devices with flexible PCBs are cameras and smartphones.

- Rigid-flex PCB. This technology joins flexible and rigid PCBs into a single unit without additional connections between them. Manufacturing becomes easier and cheaper while having the benefits of both technologies.

They can provide 10+ layer boards with traces as little as 4mil, drill sizes as small as 0.2 mm and minimum plated holes of size 0.6mm. The limits can be pushed even further by contacting sales and consulting.

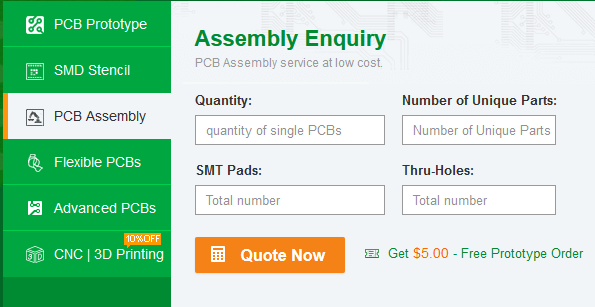

The other vital side of PCBWay is an assembly service. This step is critical after prototyping. Assembly includes applying solder paste via stencils, placing components, and soldering. Assembly is a labor-intensive process as it usually involves placing hundreds of small SMT components on the PCB surface. No human can do better than a machine. PCBWay have all the necessary equipment to set up and automate process with high reliability and quality. PCBWay can supply all the necessary parts that are needed for design. Also, you have an option to fully or partially provide them by yourself. The combo supply option is great if your design includes rare or unique parts that need special attention. Other than that, it is best to go with the complete turnkey option. Ordering of assembly is accessible through an online form where you need to choose supply option, board type, number of unique SMT, and hole parts. Also, you can provide other detailed information that would help to ease the assembly process.

After submitting the necessary information, you can instantly see the estimated price, including shipping. The price is broken down sou can see distinct manufacturing and shipping costs. Both - PCB prototype and assembly delivers the working electronics device to your doorway. Turnaround can be only a couple of days – 1 day for prototyping and another for the assembly, the significant time is taken by shipment. PCBWay offers different shipping methods that may depend on the country of your residence. DHL, FedEx, China Post, UPS, and other prices vary depending on the selected carrier. You also have various payment methods available: PayPal, Western Union, Direct Bank Transfer. VISA is also accepted through PCBWay, making it very convenient for certain paymasters who prefer this method.

The non-complex PCB prototype can cost $5 and PCB assembly as low as $30 (without parts included). And most likely, you find a small heartwarming gift inside your package.

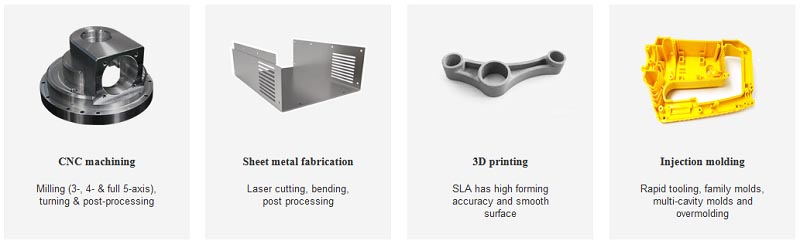

If you are going towards a finished product with an enclosure or need a nonstandard mechanical part, PCBWay offers fast prototyping services. They are building a nice set of technologies they can offer. The main four leading fast prototyping methods to choose from:

- CNC machining. They are capable of performing milling and turning. CNC machining is robust because once CAD files are prepared and loaded, the machine can produce multiple parts quickly.

- Sheet metal fabrication. They have to prepare press and cutting forms according to CAD files, and then there is no limit on how many parts to make. The process is rapid once set up. Finished products can be finished using anodizing, plating, powder coating, and painting.

- 3D printing. PCBWay uses different printing technologies depending on the materials and properties required. The main are FDM (Focused Deposition Modeling), SLS (Selective Layer Sintering), and SLA (Stereo Lithography Apparatus).

- Injection molding. It allows manufacturing plastic parts by pressing hot plastic into molds and achieving high precision and large volumes of pretty complex parts. Usually, injection molded parts are used for enclosures.

PCBWay is serious about its quality assurance. Their main goal is zero defects with timely delivery. They use materials of well-known brands while maintaining 9001 and UL certification. More than 70 specialists ensure that all requirements we met at the highest level.

The strong community

The PCBWay has surrounded itself with a strong community. They have over quarter million registered users who contribute and, in the same way, benefit from being a so-called PCBWayer. To become a community member, all you have to do is register and start using services. By only registering, you already get a discount coupon for your first order. If your project is a simple PCB, most likely, it may be delivered for free without shipment cover. However, the most benefit comes when you start sharing your projects with the community. Here you can apply for sponsorship and even crowdfunding. They already sponsored over 23000 schools, open-source projects, make faires.

PCBWay also organizes shopping festivals, giveaways, and sales where everyone can win great prizes from gift-shop, get cash rewards and valuable coupons. The win-win ecosystem helps to grow both sides and learn from each other.

Final word

PCB manufacturing market is very competitive. As a potential customer, you should be looking for the lowest price, best quality, quick turnaround times, and excellent customer support. PCBWay appears to bring all these values into one place. By opening the front page of their website (https://www.pcbway.com/), you are pleasantly greeted with all you need to start ordering your first PCB. No matter if you order a single small PCB or complex multilayer Rigid-Flex PCB, you are treated equally and respectfully. It is best to try it yourself and see the results.