This post marks the beginning of a new series of developments with an emphasis on our most comprehensive offering at Seeed Fusion, turnkey PCB assembly (PCBA). Each month for the next few months, we’ll be announcing a new upgrade or offer for our beloved community, whether it’s special offers or easier access to our best value-added services.

To start things off with a bang, we are now including the highly acclaimed Design for Assembly (DFA) review with every PCBA order – 100% free. No prices have been hiked up or additional fees squeezed in anywhere, go ahead, check. We simply cannot understate the value of this service, and we recommend it so much that we are throwing it in completely free from now on.

With the increasing popularity of outsourcing manufacturing, faster prototyping and more frequent but smaller batch runs, verifying a design at the earliest stage becomes more and more important, if not necessary. It is no longer sufficient to wing-it and just hope things turn out for the best on the production floor, where mistakes are the most destructive.

PCB Design for manufacture (DFM) is now widespread and now considered the standard in the PCB manufacturing industry. But the scope is severely limited. With Gerber files being static images at most, DFM review can only confirm if these files can translate into a physical PCB board, and engineers can only make an educated guess when something doesn’t quite look right.

On the other hand, PCBA DFA engineers have the BOM, assembly files and technical insight at their disposal, enabling them to thoroughly check the design for otherwise invisible errors, for example:

- A 0603 land pattern when the BOM calls for 0402 – a surefire way to trigger tombstoning = poor yield,

- Unclear polarity marks resulting in tedious re-working and salvaging – if possible = costly delays and wastage,

- Missing milling slots or cut-outs for connectors – a recipe for disaster, especially since these are some of the last parts to be populated – be prepared to start again from scratch = absolute wastage.

All of these errors would be swiftly caught and remedied with the DFA review.

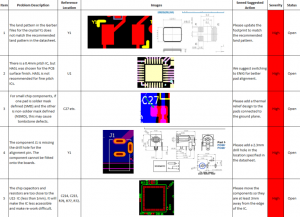

Example DFA Report

Admittedly, digging up datasheets to check the pads and positions of hundreds of parts is tedious and laborious work. No one wants to do it. But the DFA service has consistently proven itself and saved many a backside. Since it’s first introduction late last year, Seeed’s DFA engineers have consistently detected problems in over 80% of PCBA orders – 80%! Even the most meticulous of designers are not immune, one tiny hiccup can lead to weeks of delays and expensive re-runs.

Our production teams are also infinitely grateful. With fewer problems discovered at the production phase, the entire production line can operate much more smoothly and targets are easier to reach. Before the introduction of DFA reviews, stacks of delayed orders would literally pile up, waiting for customers to be contacted, boards to be re-produced or for the correct parts to come in. Now, only the most unforeseeable complications arise, and these experiences serve as valuable lessons to further improve the entire engineering and production process.

Feedback regarding the DFA service has been immensely positive, so despite the large engineering cost, we are delighted to offer this unique service for free for Seeed Fusion PCBA customers. We are confident you will not be disappointed. Find out more about the Design for Assembly service.

Power-Up your PCBA experience with Seeed Fusion. Utilize the unique online quoting platform that fetches complete turnkey PCB Assembly quotations, including parts procurement and PCB manufacture in seconds. Add functional testing or programming services, then await your personalized DFA report from our in-house engineers. Get a quotation now.

Seeed has accumulated over ten years of custom manufacturing experience, supply chain knowledge and hands-on paper to product expertise. We are also dedicated to providing the smartest, most convenient, feature-packed and value-for money service possible.

Crack open a bottle of peace-of-mind or brew some sereni-tea, and let Seeed handle the rest. Stay tuned next month for the next Power-Up PCBA update.